By SOYU Machinery-Jane | 07 November 2024 | 0 Comments

How should I choose a power battery shredder?

When selecting a power battery shredder, several factors need to be considered to ensure that the equipment selected will meet production requirements and ensure operational efficiency and safety. Here are some key selection factors:

I. Crushing capacity

I. Crushing capacity

According to the output and crushing needs of power batteries, choose a crusher with appropriate processing capacity. Processing capacity is usually related to the size, power and design of the crushing chamber of the equipment.

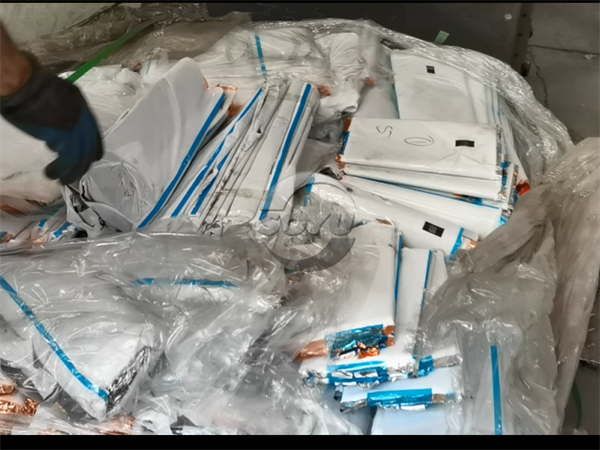

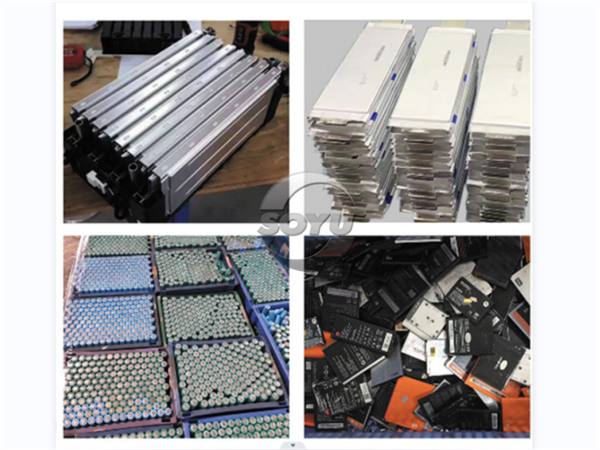

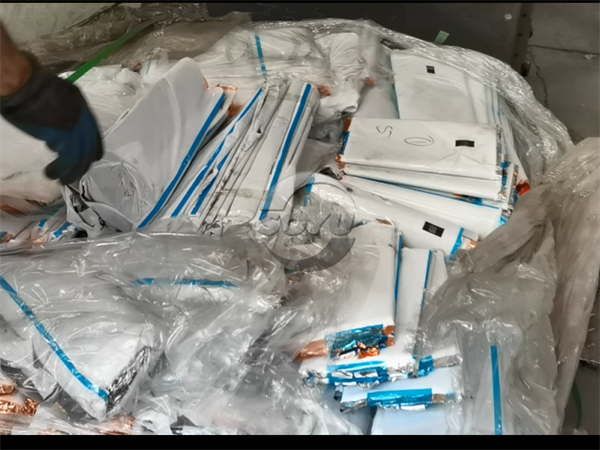

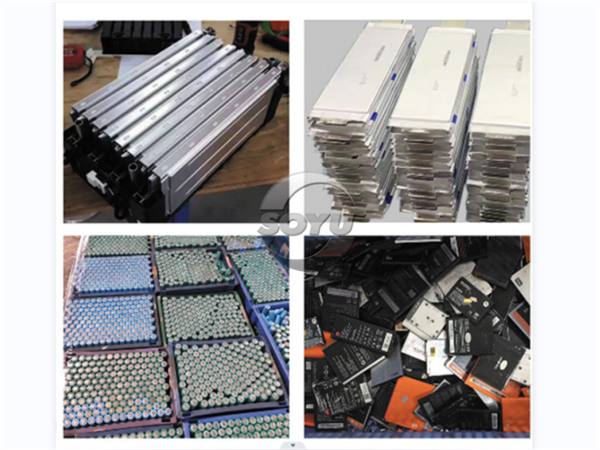

Make sure the shredder can handle different types and sizes of power batteries, including lithium-ion batteries, lead-acid batteries, etc., as well as batteries of different sizes.

II. Safety

As power batteries may contain flammable and explosive substances inside, it is crucial to choose a shredder with excellent explosion-proof performance.

Ensure that the electrical system of the equipment meets the relevant safety standards, with overload protection, short circuit protection and other safety measures.

Choose a shredder equipped with safety protection devices (such as guards, emergency stop button, etc.) to reduce the safety risks during operation. Third, stability and durability

Third, stability and durability

Shouyou is a well-known shredder brand, providing reliable quality power battery shredder, which can ensure that the equipment maintains stability and performance in long-term use.

Pay attention to the key components of the shredder (such as hammerheads, liners, etc.) material selection, preferably wear-resistant, corrosion-resistant materials to extend the service life of the equipment.

Choose a shredder that is easy to maintain to reduce operating costs. At the same time, understand the maintenance cycle of the equipment and the required materials, in order to be fully prepared. Ease of use

Ease of use

Choose a shredder with a clear and simple user interface to reduce operating difficulties and improve work efficiency.

Consider the degree of automation of the equipment, such as whether the automatic feeding, automatic discharge and other functions to further simplify the operation process.

Price and after-sales service

When comparing different brands and models of shredders, comprehensively consider the performance, price and cost-effective equipment.

Choose manufacturers that provide perfect after-sales service to ensure that the equipment can get timely and effective maintenance and support when problems occur. In summary, choosing a power battery shredder requires comprehensive consideration of a number of factors, including crushing capacity, safety, stability and durability, ease of use, price and after-sales service. Ensure that the selected equipment can meet the production requirements and ensure operational efficiency and safety.

In summary, choosing a power battery shredder requires comprehensive consideration of a number of factors, including crushing capacity, safety, stability and durability, ease of use, price and after-sales service. Ensure that the selected equipment can meet the production requirements and ensure operational efficiency and safety.

According to the output and crushing needs of power batteries, choose a crusher with appropriate processing capacity. Processing capacity is usually related to the size, power and design of the crushing chamber of the equipment.

Make sure the shredder can handle different types and sizes of power batteries, including lithium-ion batteries, lead-acid batteries, etc., as well as batteries of different sizes.

II. Safety

As power batteries may contain flammable and explosive substances inside, it is crucial to choose a shredder with excellent explosion-proof performance.

Ensure that the electrical system of the equipment meets the relevant safety standards, with overload protection, short circuit protection and other safety measures.

Choose a shredder equipped with safety protection devices (such as guards, emergency stop button, etc.) to reduce the safety risks during operation.

Shouyou is a well-known shredder brand, providing reliable quality power battery shredder, which can ensure that the equipment maintains stability and performance in long-term use.

Pay attention to the key components of the shredder (such as hammerheads, liners, etc.) material selection, preferably wear-resistant, corrosion-resistant materials to extend the service life of the equipment.

Choose a shredder that is easy to maintain to reduce operating costs. At the same time, understand the maintenance cycle of the equipment and the required materials, in order to be fully prepared.

Choose a shredder with a clear and simple user interface to reduce operating difficulties and improve work efficiency.

Consider the degree of automation of the equipment, such as whether the automatic feeding, automatic discharge and other functions to further simplify the operation process.

Price and after-sales service

When comparing different brands and models of shredders, comprehensively consider the performance, price and cost-effective equipment.

Choose manufacturers that provide perfect after-sales service to ensure that the equipment can get timely and effective maintenance and support when problems occur.

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- What kind of metal chips processing is the iron chip shredder suitable for?

- Features of Titanium Chip Shredder

- Application of woven bag shredder

- How to deal with fibreglass waste by four-shaft shredder

- [Retired wind turbine blade shredding &crushing recycling equipment - green technology, leading the

CATEGORIES

- Four shaft shredder

- Sinlge shaft shreddder

- Two shaft shredder

- Plastic shredder

- Paper and Cardboard Shredder

- Electronic waste recycling machine

- Metal Shredding and Sorting Systems

- Wood pallet shredder

- Oil Filter Crushing&Washing&Recycling Machine

- OCC Paper Dry Pulping Line

- Retired wind turbine blade shredding

TAGS